The biggest threat to the lifespan of metal parts? Without a doubt the corrosion. To protect components effectively, conventional coating simply isn’t enough. The layer needs to be uniform, adhere firmly, and reach even the most hard-to-access areas. The solution? Cathodic electrodeposition coating (KTL). Let’s take a closer look at how it works.

How cathodic dip coating works

KTL is a type of electrophoretic coating, which means the paint is applied using an electric current. The metal part is suspended on the cathode (negative pole) and immersed in a water-based paint bath. When voltage is applied, paint particles begin to move and evenly deposit themselves across the entire surface of the part. Next comes the polymerisation phase – in simple terms, the part is baked in an oven, where the coating cures and develops the desired technical properties.

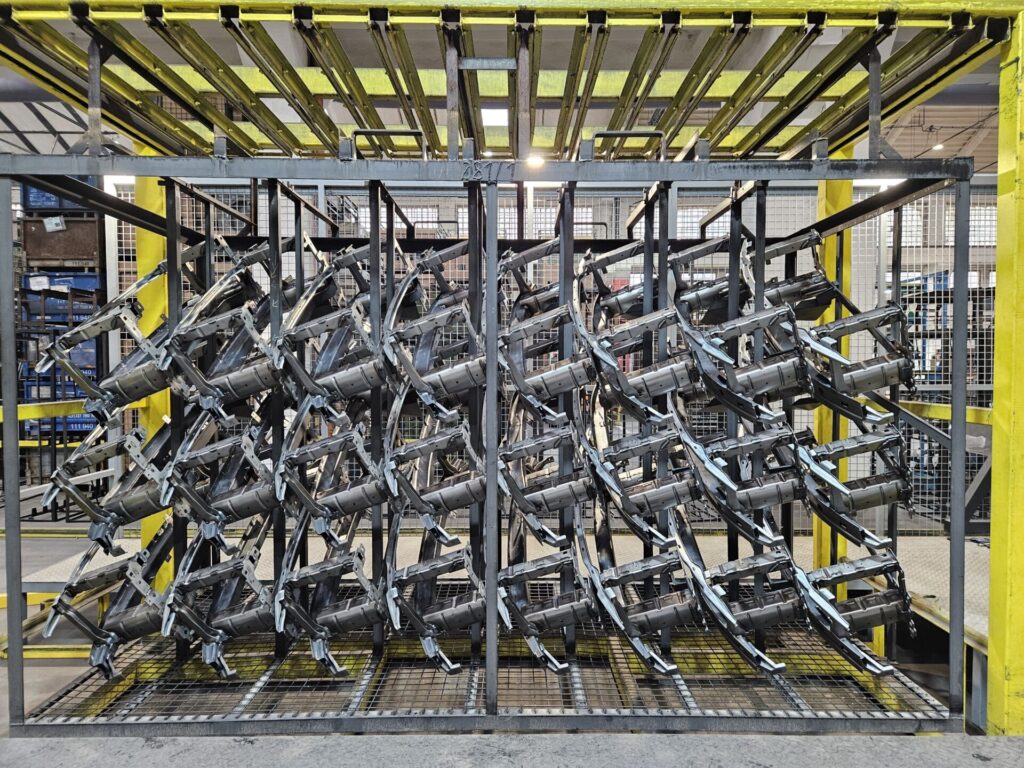

The result is a durable, compact layer that adheres even to hard-to-reach areas – such as welds, sharp edges, internal cavities, or complex geometries.

Why is cathodic dip coating so effective

Unlike traditional spraying or dipping, cathodic e-coating doesn’t rely on passive paint deposition, but it uses a targeted electrochemical reaction. Thanks to this, the coating is always uniform with a precisely defined thickness. The entire part is thoroughly covered, including areas that conventional spray guns can’t reach.

Another major advantage of cathodic dip coating is its efficiency – paint utilisation exceeds 99.5%. This leads to significantly less waste and material loss. At the same time, it’s a more eco-friendly coating option, as it uses water-based paints with low levels of organic solvents.

Where is cathodic dip coating used?

Cathodic dip coating was originally developed for the automotive industry, which places extremely high demands on the durability and corrosion resistance of components. Today, it’s used across a wide range of industries that require not only corrosion protection, but also a reliable base layer for additional coatings or powder coating. Here are some key application areas:

Automotive: Bodywork, frames, chassis parts, reinforcements, inner door structures, engine bay components, engine and transmission brackets, and more.

Agricultural Machinery: Frames of tractors, harvesters, mowers, ploughs, protective covers, components exposed to dirt and moisture, loading surfaces, and other structural parts.

Home Appliances: Metal parts of washing machines, dryers, refrigerators, dishwashers, water heaters, tanks, ovens and stoves, freezer and refrigerator components.

Furniture and Household Fixtures: Metal legs of tables and chairs, frames and structures, garden furniture, shelving supports, railings, fence components and gates, metal office furniture elements, and more.

Engineering and Structural Components: Beams, frames, building structures, covers and protective panels, distribution boxes, conveyor and handling system components, industrial racking, valves, piping, and various other technical parts.

Considering cathodic dip coating?

If you manufacture or work with metal components, cathodic dip coating is one of the most effective ways to improve quality. Especially for parts with complex shapes, sharp edges, or internal cavities. It also provides long-term corrosion protection and is ideal wherever a uniform, repeatable coating or a reliable base for additional layers is required.

Looking to boost quality and efficiency? Planning to reduce your environmental footprint?

If so, get in touch. We’ll be happy to help you find the right solution.