Cathodic dip coating (KTL)

Cathodic dip coating (KTL)

Premium Anti-corrosion protection for metal parts

How does cathodic dip coating (KTL) work?

How does cathodic dip coating (KTL) work?

Cathodic Dip Coating (KTL) is a modern metal surface treatment process that uses an electric current to apply paint from a water-based bath. This technology relies on electrophoresis to ensure even coating, even on the most complex shapes. KTL is an ideal choice for manufacturers who prioritise long-term durability, environmental responsibility, and the efficiency of mass production.

The parts are submerged in a water-based bath containing a paint suspension, and under the influence of direct current, the paint adheres evenly, even to hard-to-reach areas. After rinsing, the parts are cured in an oven to harden the coating. The result is a highly durable, uniform, and corrosion-resistant layer, ideal as a primer for further coating or as a final protective finish.

The cathodic dip coating process

The cathodic dip coating process

The cathodic dip coating is a modern metal surface treatment process in which paint is applied using an electric current from a water-based bath. It uses electrophoresis – the movement of electrically charged paint particles toward an electrically charged metal parts.

Step-by-step process:

1.

Surface pretreatment

Metal parts are first thoroughly degreased, rinsed, and chemically treated (e.g. phosphating) to ensure strong adhesion of the coating.

2.

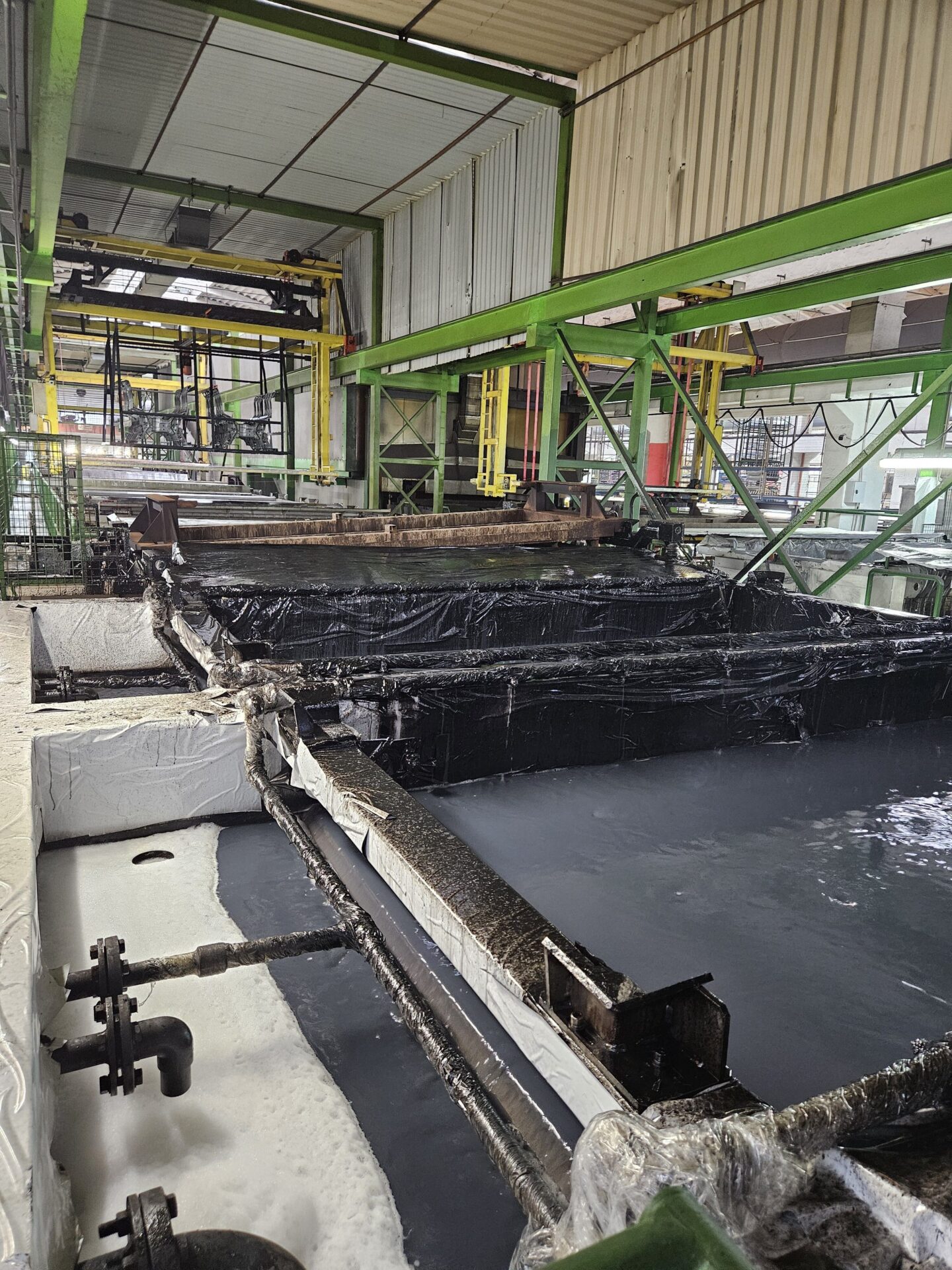

Cathodic dip coating bath

The parts are immersed in a water-based bath containing finely dispersed paint particles. A direct current is applied – the part acts as the cathode (-) and the bath electrodes as the anode (+).

3.

Rinse and recycle

After the coating is applied, excess paint is rinsed off and recycled back into the system. This significantly reduces waste.

4.

Polymerisation

The final step is polymerisation in an oven at approximately 180°C. This process hardens the paint layer, giving it its final mechanical and chemical properties, including corrosion resistance.

The result:

Uniform coating even on complex geometries

High resistance to corrosion, chemicals, and mechanical damage

Ideas as a primer for further painting or as a final finish

Typical applications of E-coat

Typical applications of E-coat

Cathodic dip coating (also known as KTL or E-coat) is widely used wherever reliable and long-lasting corrosion protection for metal parts is essential. Thanks to its high uniformity and durability, KTL is ideal both as a primer before additional coating and as a standalone protective layer. It is an environmentally friendly coating method that significantly extends the service life of metal parts. KTL is an immersion coating process. Takt-based KTL technology combines excellent resistance to corrosion, chemicals, and mechanical damage with the efficiency required for mass production.

Automotive industry

Automotive industry

- Car bodies, chassis, control arms, axles, brackets, reinforcements

- Mass coating of serially produced metal parts

Engineering and metal fabrication

Engineering and metal fabrication

- Structural frames, enclosures, machinery and equipment parts

- Ideal for components exposed to moisture or harsh environments

Agricultural and construction equipment

Agricultural and construction equipment

- Tractors, trailers, frame parts, hydraulic components

- Long-term protection under demanding conditions

Furniture, appliances, metal shelving

Furniture, appliances, metal shelving

- Load-bearing structures, profiles, assembly parts

- Both aesthetic and protective function

Healthcare and public sector

Healthcare and public sector

- Metal components in hospital equipment, public spaces, and transport infrastructure

E-coat technical specifications

E-coat technical specifications

| Specifications | Nymburk | Police nad Metují |

|---|---|---|

| Production cycle time | Flexible 8.5 min +/- 10% | Flexible 8.5 min +/- 10% |

| Daily cycle count | 153 - 187 | 153 - 187 |

| Maximum surface area per cycle | 100 m² | 100 m² |

| Maximum surface area per cycle | 2200 kg (including the suspension equipment) | 1850 kg (including the suspension equipment) |

| Maximum weight load per cycle – net production weight | 1.500 kg | 850 kg |

| Cycle type | Closed | Open |

| Technical capacity m2 – per year at 24/7 operation | 5.000.000 m² | 5.000 000 m² |

| Current operating mode | 24/7 | 24/5 |

| Maximum size of coated product | 3.500 x 2.000 x 1.500 mm | 3.500 x 2.000 x 1.500 mm |

| Technology | BASF Cathoguard 570F (black) |

BASF Cathoguard 570F, HENKEL - Bonderite |

| Alkaline degreasing | 4-stage with pre-degreasing | 3-stage with pre-degreasing and spraying |

| Acid degreasing/pickling | Yes | Yes |

| Control system | Simatic/reliance (display) | Simatic |

| Hanging equipment | 100% mutually interchangeable (NBK x Police) | 100% mutually interchangeable (NBK x Police) |

| Number of manipulators | 6 | 6 |

| Entry/exit | Hydraulics | Electric drive |

| Pre-treatment heating | Gas | Gas |

| Paint heating/cooling | Electric | Electric |

| Polymerisation oven heating | Gas | Gas |

| Throughput time | 4-5 hours | 4-5 hours |

Both facilities are identical in terms of technology, chemistry, and performance. This ensures full interchangeability and a clearly defined production backup for our customers.

Gallery

Gallery

Contact

Contact

Are you looking for high-quality, efficient KTL painting for your parts? Do you need production line automation, complete part manufacturing, or special applications?

Contact us and let our expertise drive your project forward!

Karel Magušin

Business Development Manager Central and Eastern Europe